Alamos Gold Inc. (Alamos), headquartered in Toronto, Canada, employs approximately 400 people in Mexico and has ambitious plans for growth through optimizing production, mine expansion, new production from the Escondida area, increasing reserves, and an aggressive and innovative exploration program. Alamos is committed to accomplishing this while maintaining a strong balance sheet and ensuring that growth occurs in a reasonable, responsible and rational manner.

Alamos owns 100% of the 28,500-hectare Salamandra group of concessions located in the state of Sonora in northwest Mexico. The Salamandra group of concessions includes the Mulatos mine and more than nine other prospective exploration targets. Mulatos is a high sulfidation, epithermal gold deposit occurring in oxide, mixed oxide/sulfide and sulfide ore types containing approximately 4 million ounces of gold resources. In April, 2006, the Mulatos Mine achieved commercial production.

Alamos continues to outline new resources and reserves in deposit adjacent to Mulatos. The 2005 discovery of the high-grade Escondida Hanging Wall Zone just 500 meters from the Estrella Pit demonstrates the excellent exploration potential of the Salamandra property. Alamos is currently exploring for new ore deposits throughout the Mulatos District.

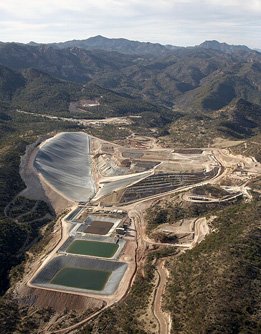

Construction began in the third quarter of 2004. The first gold pour occurred in July 2005 and by December the major components of the mine, including the gold recovery plant, Phase One of the leach pad and facilities to accommodate 250 full-time workers were in place. Construction and commissioning were substantially completed in December 2005. The total cost to complete construction of the Mine was approximately $74 million.

The Mulatos Mine is pictured above. By year end 2005, mining of 830,000 tonnes of ore and the removal of 4.6 million tonnes of waste from the Estrella Pit were complete. In 2006, the waste-to-ore ratio will be 2:1, higher than feasibility levels because the faster mining rate requires more working room for the equipment, but the average life-of-mine ratio of 1.4:1 for the Estrella Pit remains unchanged.

Mining is by conventional open-pit methods using 12.3 m3 front end loaders and fourteen 90 to 100-ton haul trucks. The 2006 mine plan calls for ore to be crushed in a three stage crushing circuit at a rate of 15,000 tonnes per day (tpd), 50% above the feasibility study level, by the end of the second quarter. The crushed ore is then conveyed to, and stacked on,

the leach pad.

The following link will open up in a new window: www.alamosgold.com

|

|